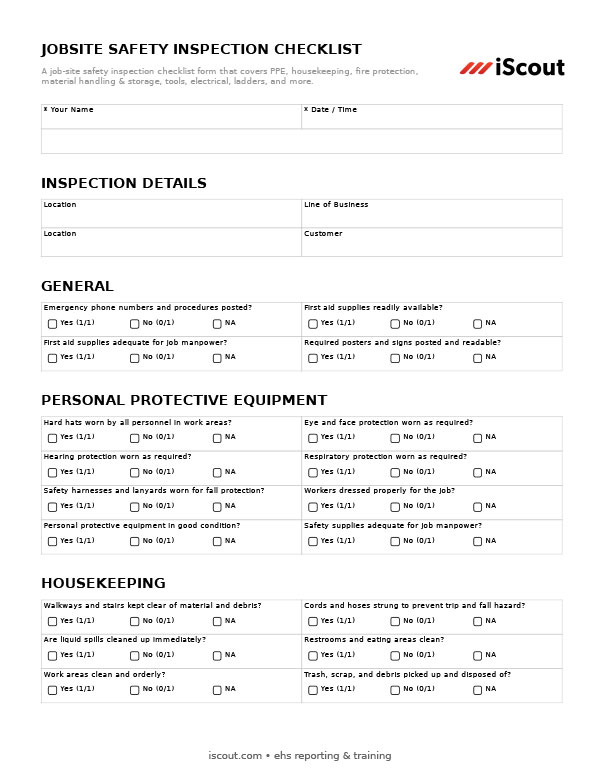

Jobsite Safety Inspection Checklist Form

A job-site safety inspection checklist form that covers PPE, housekeeping, fire protection, material handling & storage, tools, electrical, ladders, and more. Checkout the Forms Library »

What is a Jobsite Safety Inspection Checklist?

A Jobsite Safety Inspection Checklist is a high-level audit identifying whether or not a work-site is following standard, general safety procedures. Questions include:

General

- Emergency phone numbers and procedures posted?

- First aid supplies readily available?

- First aid supplies adequate for job manpower?

- Required posters and signs posted and readable?

Personal Protective Equipment

- Hard hats worn by all personnel in work areas?

- Eye and face protection worn as required?

- Hearing protection worn as required?

- Respiratory protection worn as required?

- Safety harnesses and lanyards worn for fall protection?

- Workers dressed properly for the job?

- Personal protective equipment in good condition?

- Safety supplies adequate for job manpower?

Housekeeping

- Walkways and stairs kept clear of material and debris?

- Cords and hoses strung to prevent trip and fall hazard?

- Are liquid spills cleaned up immediately?

- Restrooms and eating areas clean?

- Work areas clean and orderly?

- Trash, scrap, and debris picked up and disposed of?

Fire Protection

- Fire protection equipment well marked and accessible?

- Employees trained to use fire protection equipment?

- Fire extinguishers inspected monthly?

- Smoking prohibited where flammables are located?

- Flammables stored and handled in approved containers?

- Oily rags disposed of in an approved container?

Material Handling and Storage

- Materials stored neatly in stacks or piles?

- Cylindrical materials racked or cribbed and blocked?

- Loose materials containerized or palletized?

- Aisle space maintained around stored materials?

- Storage areas kept clear of scrap, debris, and trash?

- Slings and chokers in good condition?

- Chain falls and come-a-longs in good condition?

- Cranes operated in a safe manner by operators?

- Workers move from under suspended loads?

- Workers know and use proper crane signals?

- Crane hand signals posted on jobsite?

- Workers attach tag lines to loads?

- Hoisting hooks have safety latches?

- Running cables inspected and in good condition?

- Load limits marked on all hoisting rigs?

Tools

- Power tools have guards in place?

- Power tools either grounded or double insulated?

- Power tool cords and plugs in good condition?

- Impact tools with mushroomed heads dressed as needed?

- Broken tools repaired or replaced as needed?

Welding and Cutting

- Gas cylinders stored upright and secured?

- Oxygen cylinders segregated from fuel gas cylinders?

- Full cylinders segregated from empty cylinders?

- Caps secured on all cylinders not in use?

- Welding leads in good condition?

- Welding screens erected in high flash areas?

- Welding blankets used to protect materials/equipment?

- Fire watches posted as needed?

- Proper permits issued (as required)?

- Fire extinguishers kept close to hot work areas?

Electrical

- 120 volt tools and equipment tested and color-coded?

- Extension cords heavy duty, 3-wire type?

- Temporary lights equipped with bulb guards?

- Sufficient lighting to work and move safely?

- Lockouts used to de-energize operational systems?

- Welders and stationary equipment properly grounded?

Ladders

- Straight ladders secured at top landing?

- Straight ladders extend 36" above top landing?

- Straight ladders have feet or blocked at bottom?

- Straight ladders set up with a 4 to 1 slope?

- Top step of stepladders not used as a step?

- Climbing the back of stepladders prohibited?

- Workers use the proper height ladder for the job?

- Portable ladders used only by company employees?

Scaffolds and Manlifts

- All scaffold parts and hardware used as required?

- All scaffold hardware and parts in good condition?

- Scaffolds fully planked?

- All scaffold planks cleaned?

- Scaffolds have guardrails, midrails, and toe boards?

- Wheels on rolling scaffolds locked during scaffold use?

- Workers prohibited from riding rolling scaffolds?

- Manlifts in good operating condition?

- Only trained employees allowed to operate manlifts?

- Outriggers extended when manlifts are in use?

- Workers prohibited from exiting raised manlifts?

- Workers only allowed to work from floor of basket?

- Workers required to tie-off while basket is raised?

Handrails and Hole Covers

- Perimeters and drop-offs protected by rails or cables?

- Railings sturdy, continuous, and have midrails?

- Railings replaced after temporary removal?

- Floor holes protected by railings or hole covers?

- Hole covers secured to prevent movement?

- Hole covers marked to prevent accidental removal?

- Hole covers replaced after temporary removal?

Excavation and Trenching

- Excavations 5' or deeper shored, sloped, or boxed?

- Workers stay within shored area?

- Excavated spoil stored at safe distance from work?

- Barricades placed on all open sides at end of shift?

- Ladders placed every 50' for entry and egress?

- Excavations de-watered as needed?

- Backfill placed as soon as possible?

Communications

- Do crew leaders communicate with their crews on job methods?

- Do crew leaders react to employee safety recommendations?

- Do crew leaders address unsafe actions and conditions?

- Are safety meetings held weekly with all employees?

This form is a sample report which can be imported into your KPA Flex account. All forms including this one can be easily modified to fit your organization's policies and procedures.

Don't have a KPA Flex account? Download the printable Jobsite Safety Inspection Checklist PDF form so your team can fill out a paper copy.

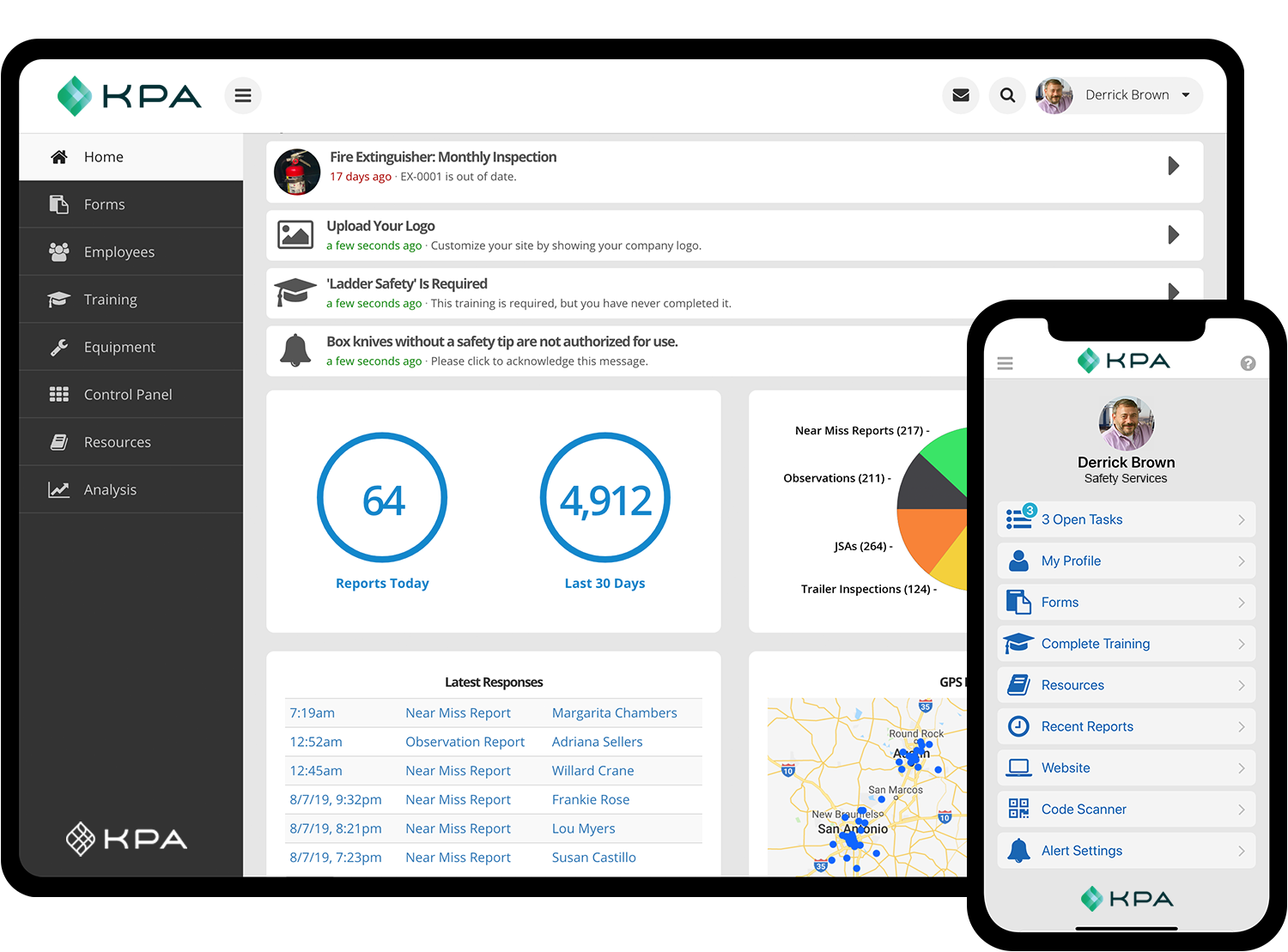

Top Features of KPA Flex Reporting

Check out the Forms Overview or learn about specific features:

Form Builder »

Start from a pre-built template or design your own form from scratch.

Offline / Mobile Reporting »

Once team members have downloaded the app, they can fill out reports offline - including attachments! The report will automatically upload once connectivity resumes.

Follow-Up Tracking »

Assign follow-ups within a report and track incomplete items.

Permissions »

You decide who can submit reports, view responses, and more.

Alerts & Notifications »

Setup individual or group notifications for certain reports. For example, you may want notifications for critical issues but not minor ones.

Analysis Tools »

KPA Flex automatically generates rich analytic tools so you can filter, visualize, and export all the data you're collecting.

Participation Reports »

Run participation reports to see who is submitting reports and when they're being submitted.

Electronic Signatures »

Collect electronic signatures when your team fill out reports.

Multilingual »

Forms filled out through the web browser can be automatically translated into 100+ languages.

Revision History

As your team edits a report, the system will automatically track what was changed, the author, and the date.

Data Lists

As projects, locations, etc change, the form will automatically update to include the latest options.

Auto-Hiding Fields

Clicking "Does Not Apply" dozens of times is counter-productive. Instead, hide questions that don't apply.

Sub-Reports

Some forms can be extremely complex, but that's no problem in KPA Flex. Setup sub-reports to make it easier to fill out in sections.